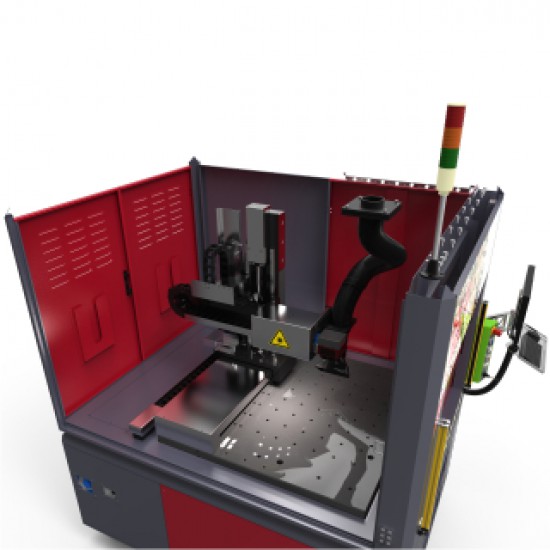

Laserator TUWANA XYZ Laser Work Station

- Model: TUWANA-XYZ

Laserator 2D, 2.5D and 3D Laser Software

Packages for Laser Machinings

Laserator laser marking and engraving software enables an operator to mark on any surface of a 3D or 2D shaped part by using the unique and innovative Laserator 2D and 3D scan heads. After the operator, for instance, imports an STL extended 3D drawing to the desktop of the Laserator3D, he can easily place that drawing on the template model of that 3D workpiece that is positioned correctly at the correct angle in the software. The rest is to position the workpiece at the right angle and the right place and start the lasing operation after he makes the parametric adjustments. For an automatic positioning process of the machine, we also offer coaxial or paraxial camera set. The Laserator3D software not only imports to the desktop any STL extended files to be processed but also imports 3D DXF extended files to be used as pre-defined template surfaces. During the lasing process, the operator can follow up the operation layer by layer in both 2D and 3D view mode of the software. The operator can also assign different parameters to the different layers to be processed. A lasing process can be completed either using the mechanic Z-axis as a focal length changer or fast and accurate focal length optics in the 3D scan head of the TUWANA.

THE INDUSTRIES WHERE TUWANA XYZ WORKSTATIONS CAN BE OPERATED

- Automotive Industry - Surface Texturing & Plastic Welding Operations

- Mold Industry - 3D Engraving, 2.5D Engraving, Deep Engraving, Shoe Sole Mold Texturing & Deep Engraving

- Watch & Jewellery Industry - 3D Mold Processing, 2.5D Mold Processing, 3D Mold Marking, 3D Mold Sanding, 2D Surface Sanding, Micro Character Type Engraving, 2D& 3D Marking, Gold & Silver Cutting Operations

- Coin Mold Manufacturing Industry - 3D Engraving, 2.5D Engraving, 2D & 3D Sanding, Surface Texturing

- Tools Manufacturing Industry - 3D Marking

- Fire Arms Industry - 2D & 3D Marking, 2.5D & 3D Engraving

- Medical Industry - 2D & 3D Marking

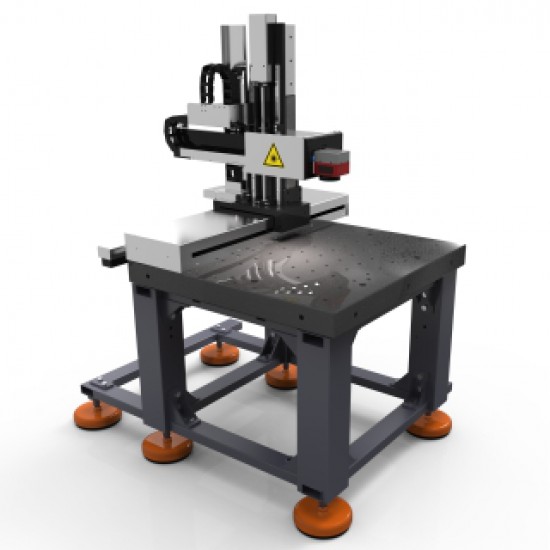

TUWANA XYZ SPECIFICATIONS

- X:900mm, Y:600mm, Z:480mm Volumetric Lasing Environment

- Granite Work Table Dimensions: 1000X1000X100mm

- Unique & Innovative 2D or 3D Galvo Scan Head

- A Strengthful Combination of Steel & Granite

- Rigidity by Its Heavy Duty Large Damping Feet

- 2000kgs in Weight

- Granite Worktable, Colum, & Steel Cars

- Automatic 3-Piece Synchronous Door with a 1064nm Laser Protective Glass at Front and Manual Doors at Both Sides

- Powerful Emission & Filtration System for Dust & Smoke

- Finger Protection Sensors at Front Door

- 3D Engraving By an Optional Optical Z-Axis

- 2,5D Engraving By an Optional Indexing Z-Axis▪ User Defined Many Types of Laser Sanding Operations

- Optional External Cameras and Software Modules for Close-up Views of lasing processes

- Optional Coaxial Camera for Exact Positioning

- Optional Paraxial Cameras for Depth Measurement

- Inner-Enclosure Day-Light LED-Illumination Lamps

- Red & White LED-Light Local Illumination Rings

- 50W, 60W, 70W, 90W, 100W & 120W Fiber Laser Engines to Choose From

- Optional 1D, 2D Code Reading Camera, and Software

- 180 Degree Indexing C-Axis

- Rotary Axes with Different Sizes of Chucks for Different Work Pieces

- All Axes are Servo Driven

- Climate Control For Automation Panel

OPTIONAL SPECIFICATIONS

- 2,5 Axis Lasing w/ a 2D Galvo Scan Hea

- 3 Axis Lasing w/ a 3D Galvo Scan Head

- 4 Axis Machining w/ a Rotary Axis

- 4 or 5 Axis Machining w/ a C Axis

- Positioning with Coaxial or Paraxial Cameras

- Camera for close follow-up of lasing operation out of the enclosure

- 3 Axis Galvo Scan Head

- Laserator 50W, 60W, 70W, 90W, 100W, 120W OEM Fiber Laser Engines To Choose From

- Dust and Smoke Emission & Filtration

- 3D Digital Scanner for Digitizations of 3D Parts